Cost Reduction

By inspecting the tank while in-service we eliminate the costs associated with a tank turn-around

Safety

In-service inspections minimizes the need for confined space entry

Environmental

In-service inspections minimizes the time the tank is open and eliminates the need for sludge removal

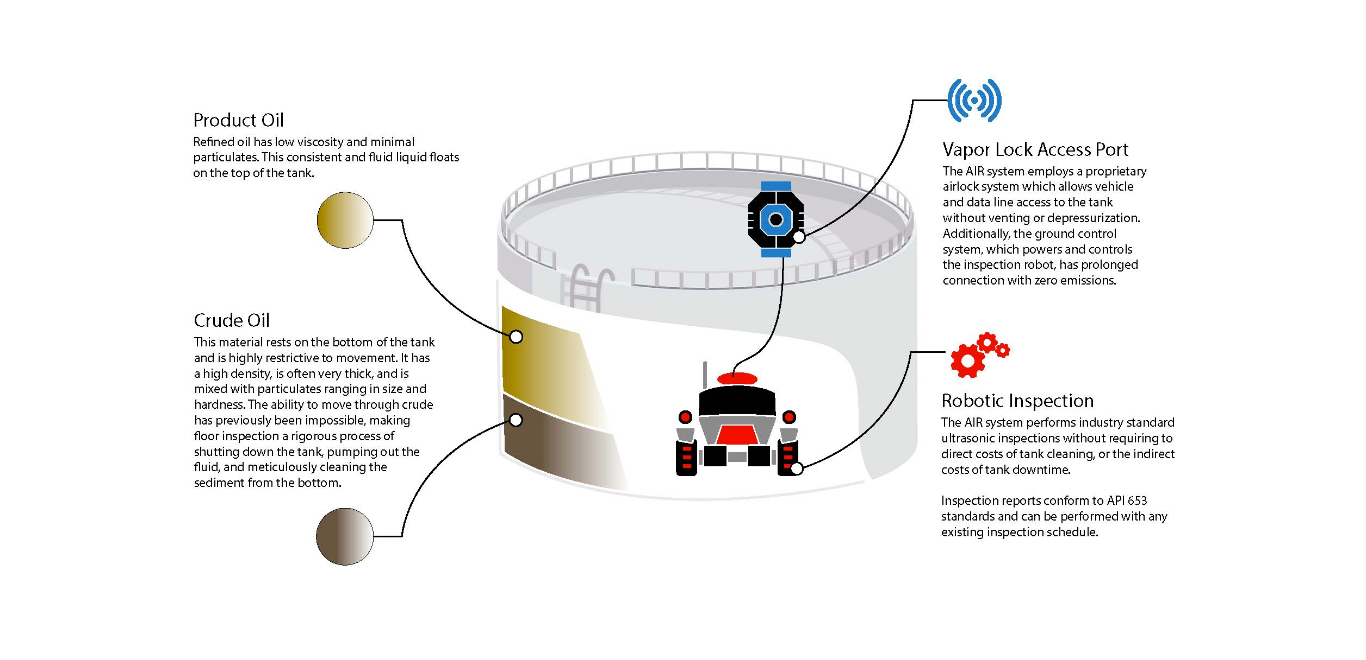

Applied Impact Robotics is developing a robotic solution capable of inspecting a crude oil tank floor while the tank remains in-service. By starting with a clean slate and using biomimicry our solution is unique in its ability to reduce viscosity of the sludge in a localized way. We leverage this reduced viscosity for penetration and maneuvering directly through the sludge and sediment to position sensors for floor scanning. By utilizing conventional UT sensors which are accepted as part of the API653 standard we can seamlessly integrate into your environment and provide high quality scan. By keeping the tank in-service during the scan, we significantly reduce the number of man hours required for confined space entry.

Our Partners

Building the future together

February 08, 2023

February 08, 2023